2020 Photo Gallery

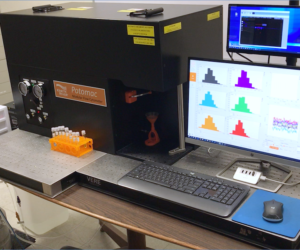

Potomac Cytometer Installation, National Research Council, 2020, Naples

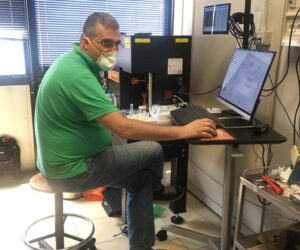

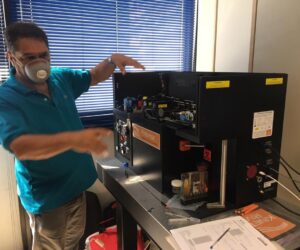

Dr. Paolo Cappella, of KRC partner Cytoflow Service, installing the Potomac at the Institute for Electromagnetic Sensing of the Environment (IREA) at the National Research Council (CNR) in Naples, Italy. © 2020–2022 Cytoflow Service

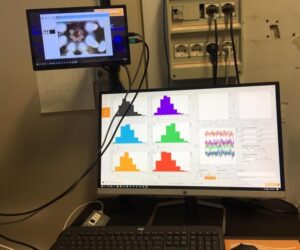

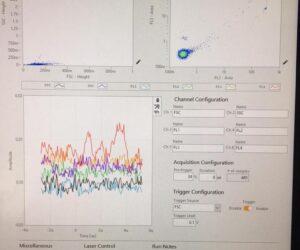

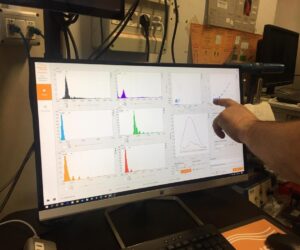

The Potomac installed at the CNR featured KRC's Panama Flow Cytometry Software. © 2020–2022 Cytoflow Service

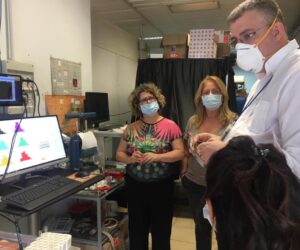

Giovanni Contini, of Cytoflow Service, delivering user training on the Potomac. © 2020–2022 Cytoflow Service

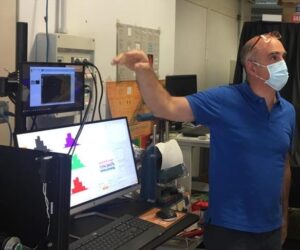

Giovanni Contini validating the Potomac performance during installation. © 2020–2022 Cytoflow Service

The Panama software on the Potomac offers the user great flexibility with detection parameters. © 2020–2022 Cytoflow Service

The IREA-CNR user group includes biologists and physicists as well as environmental scientists. © 2020–2022 Cytoflow Service

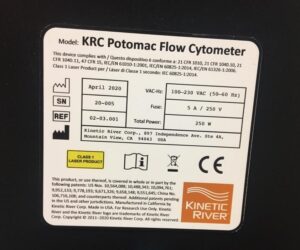

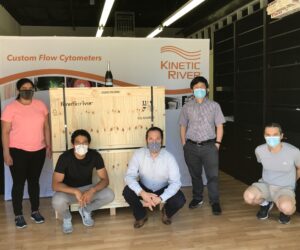

Potomac Shipment, 2020

This shipment took place at the height of the first wave of the Covid pandemic in 2020, adding a layer of complexity to the process. © 2011–2022 Kinetic River Corp.

The Potomac underwent several layers of packing for protection during international shipping. © 2011–2022 Kinetic River Corp.

Vacuum-sealing the entire instrument ensured stability and moisture protection. © 2011–2022 Kinetic River Corp.

The crate housed the instrument mainframe as well as monitors, fluid tanks, and other accessories. © 2011–2022 Kinetic River Corp.

Shock and tilt sensors were used to help prevent mishandling during shipment. © 2011–2022 Kinetic River Corp.

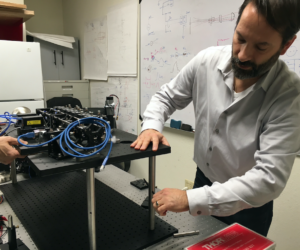

Kinetic River's founder and president, Dr. Giacomo Vacca, with the finished crate ready for shipment. © 2011–2022 Kinetic River Corp.

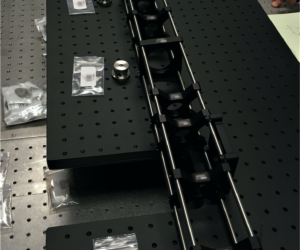

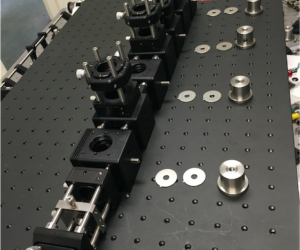

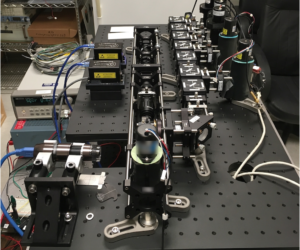

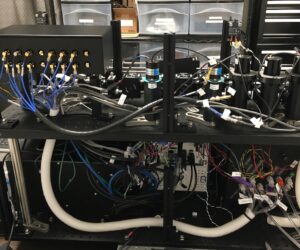

Potomac Assembly, 2020

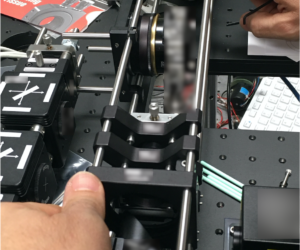

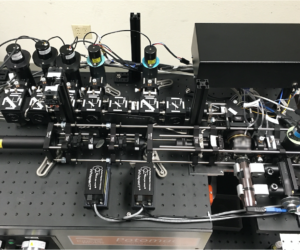

Foundation of the Potomac optical bench--a honeycomb breadboard with custom cutouts. © 2011–2021 Kinetic River Corp.

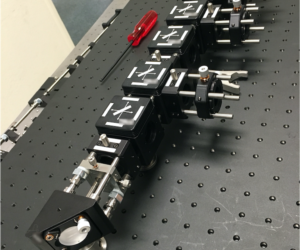

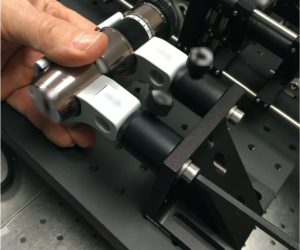

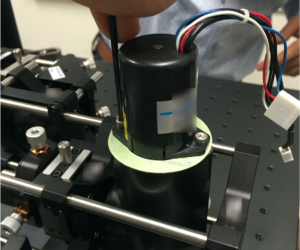

Alignment of the excitation arm is designed in by using a cage assembly. © 2011–2021 Kinetic River Corp.

Optical components for beam shaping are mounted in the cage assembly brackets. © 2011–2021 Kinetic River Corp.

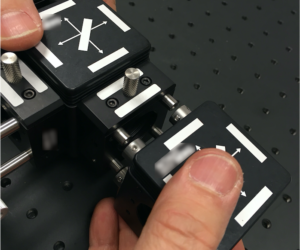

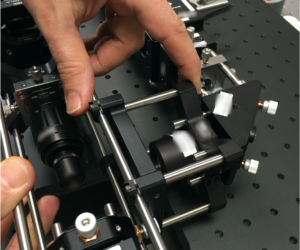

Highly stable flexure mounts make for a very reproducible alignment process. © 2011–2021 Kinetic River Corp.

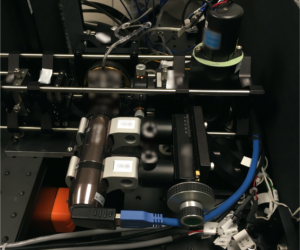

Mounting of the detection arm to ensure mechanical stability and robust alignment. © 2011–2021 Kinetic River Corp.

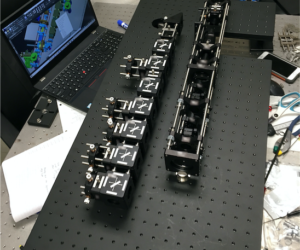

The two main optical modules—excitation arm and detection arm—side by side before integration. © 2011–2021 Kinetic River Corp.

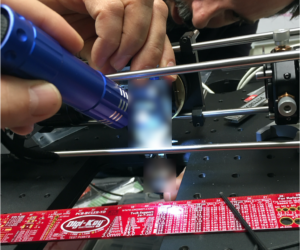

Mounting of precision achromatic lenses to accommodate a wide range of excitation wavelengths. © 2011–2021 Kinetic River Corp.

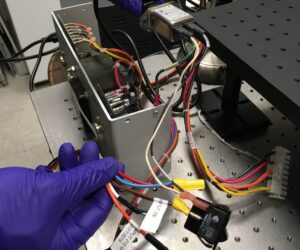

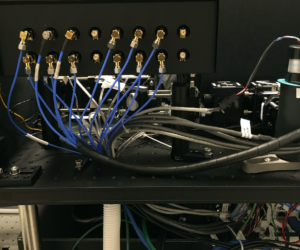

The "second-floor" optical bench is mounted above the "first floor," site of power, electronics, and fluidics. © 2011–2021 Kinetic River Corp.

All the detectors on the Potomac are PMTs, giving superior sensitivity also for the scattering channels. © 2011–2021 Kinetic River Corp.

Assembly of the optical components occurs according to a validated procedure. © 2011–2021 Kinetic River Corp.

The lenses used on the Potomac are high-quality, precision optical components for maximum sensitivity. © 2011–2021 Kinetic River Corp.

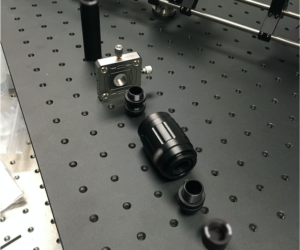

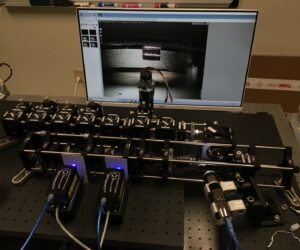

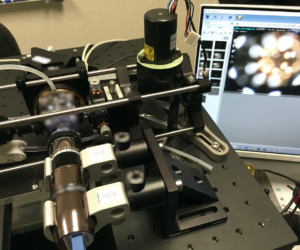

The flowcell monitoring microscope provides indispensable information about beam alignment and core stream stability. © 2011–2021 Kinetic River Corp.

The microscope is prealigned during assembly, giving the user the ability to remotely fine-tune the focus, without having to open up the instrument. © 2011–2021 Kinetic River Corp.

This Potomac was built to accommodate an external 266-nm laser (see optical tube at left). © 2011–2021 Kinetic River Corp.

The Potomac undergoes extensive testing and verification during and after assembly. © 2011–2021 Kinetic River Corp.

The Potomac incorporates the Shasta, a state-of-the-art fluidics control module. © 2011–2021 Kinetic River Corp.