“Kinetic River’s Potomac is a unique flow cytometer. We specifically requested a violet/UV excitation configuration, not available anywhere else, to meet our needs to use short wavelengths both to generate autofluorescence and to detect nanoparticles for biomedical applications. The instrument is very sensitive and easy to use, and furthermore provides the user with great flexibility, such as the possibility to access to raw waveform data.”

Romeo Bernini, National Research Council

Research Director, IREA-CNR

Case Study:

Potomac 2.0 – Developing a Custom-Made Flow Cytometer

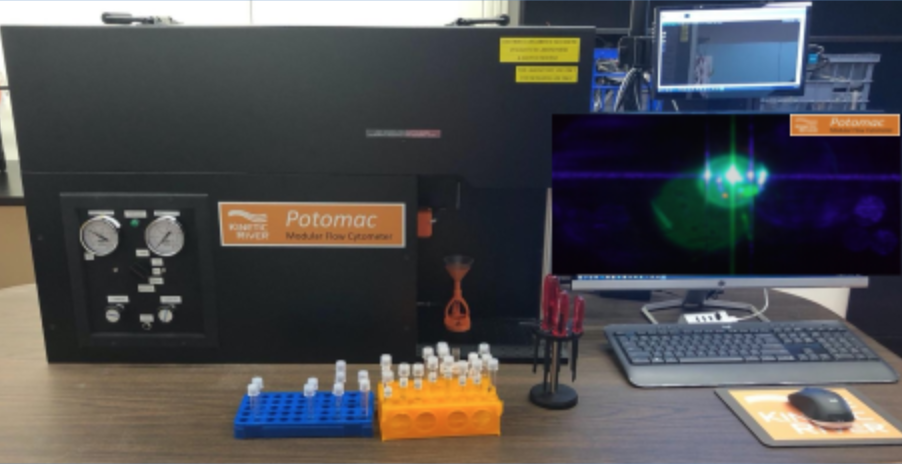

Kinetic River Corporation, a product development and consulting firm specializing in custom flow cytometers, was approached with a request to build a unique version of our flagship flow cytometer, the Potomac, for the Institute for the Electromagnetic Sensing of the Environment (IREA) of the National Research Council (CNR) in Naples, Italy. This white paper describes the process Kinetic River took in developing this custom Potomac, including redesigning the entire instrument, selecting components, assembling the optical and fluidic modules, manufacturing custom hardware components, developing a proprietary user interface, and validating the instrument’s functionality.

Figure 1. The Potomac 2.0.

The Potomac is a fully customizable flow cytometer with a range of customization options, including incorporation of exotic light sources, unusual excitation configurations, use of silicon photomultiplier detectors, and full ability to tailor flow conditions over a 1,000-fold dynamic range. Design and production of the Potomac for the IREA-CNR was carried out at Kinetic River’s laboratories in Mountain View, California.

Background

The National Research Council requested this custom build in order to run water quality tests and perform label-free analysis of biological samples. Specific instrument requirements included a unique all-violet/ultraviolet (UV) collinear excitation scheme, six detection channels (along with built-in capacity to add three more), and nanoparticle detection capabilities. Kinetic River was able to deliver a robust instrument that exceeded the National Research Council’s needs, developing one of the world’s first flow cytometers capable of exciting samples across the violet-to-deep-UV spectrum. The Potomac’s customization provides scientists at the IREA-CNR with the ability to use violet (405 nm), UV (375 nm), and deep-UV (266 nm) lasers to excite autofluorescence in human cells for biomedical applications. The instrument can also be used to measure cyanobacteria—which, also known as blue-green algae, are common contaminants in water reservoirs—enabling label-free analysis of water samples.

Defining the Requirements

The first step in the development process at Kinetic River was to work with the customer to fully define the requirements of the system. The National Research Council wanted the ability to use three separate light sources: 266-nm, 375-nm, and 405-nm. Two of those light sources (at 375 nm and 405 nm) would be incorporated internally, while the third one (at 266 nm) would be an external laser. It was critical that the instrument accommodate nine detection channels, including forward scatter, side scatter, and seven fluorescence channels. Six detectors would be populated at initial delivery, with the instrument design incorporating optomechanical support for an additional three channels. Further requirements included a two-gallon sheath tank, continuously variable flow rates, ultrasensitive small-particle detection, and the capability for each of the detection channels to receive light from any one of the three sources.

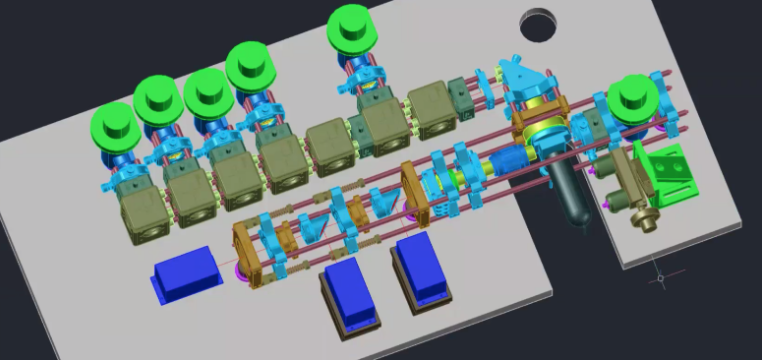

Figure 2. Optical bench of the IREA-CNR Potomac.

Figure 3. BeamWise model of the optical bench.

Designing the Optical Bench

The optical bench design began with a 2D sketch on paper. This sketch incorporated all optical elements, such as lasers, lenses, filters, beamsplitters, and mirrors. From there, Kinetic River engineers built up the full optomechanical model in BeamWise, a 3D optical system modeling program, as shown in Figure 3. The full optical bench comprises a combination of custom hardware components and of off-the-shelf parts, including mounts, stages, cage cubes, and filter holders. Most of the custom hardware components were manufactured in-house using Kinetic River’s 3D printing facilities. The BeamWise model allowed Kinetic River engineers to proactively solve any clearance or tolerance issues while providing a blueprint for construction after the parts were ordered.

After multiple rounds of review and optimization, the BeamWise model was used to generate a bill of materials for the entire optical bench. Parts were ordered from multiple vendors, including Thorlabs, Pavilion Integration, Edmund Optics, Newport, and Hamamatsu. Construction of the optical bench was completed in accordance with the BeamWise model, and then the completed optical bench was aligned and tested.

Stability and ease of alignment was critical throughout the design, especially since the three separate light sources shared the same optical path. To accomplish this, Kinetic River engineers designed and implemented optics housed in removable magnetic kinematic mounts at multiple locations to allow easy switching between light sources for the user. Furthermore, high-quality stages and mounts were used throughout the optical bench to ensure optical stability; the bench design also allows for easy alignment and adjustment by the user when needed.

Figure 4. Built-in lasers (405 and 375 nm) for the IREA-CNR Potomac.

The two built-in lasers (405 and 375 nm) are 50-mW solid-state lasers from Pavilion Integration (Figure 4). Important design factors that affected laser selection included laser power, beam quality and size, module size, and ease of integration into Kinetic River’s control firmware framework. The system was designed to allow for the third laser (266 nm) to be installed externally next to the Potomac and routed into the instrument through the external laser port, as shown in Figure 5.

Figure 5. External laser port.

Deep UV excitation and detection is unusual for flow cytometers. Kinetic River had to ensure all optical components were correctly anti-reflection coated for this portion of the spectrum, with excitation optics needing to handle light from 266 nm to the visible, and fluorescence optics needing to handle wavelengths from the UV into the deep red. Because a critical feature for user was the ability to change optical components depending on the light source, Kinetic River designed the optical bench to allow easy swapping of optical components. All beamsplitter and filter holders were designed to be plug-and-play as well, with easily swappable magnetic kinematic mounts depending on the needs of the user at any given time.

Kinetic River decided to use photomultiplier tubes (PMTs) for all channels of detection, including scattering, making the entire system more sensitive to the small particles that would be studied at the IREA-CNR. The entire optomechanical system was mounted on a cage system (Figure 6), conducive to easy adjustment and alignment of the optics. The ability to add additional detector channels was also built into the design, with six detectors shipped to the customer and room for three additional detectors to be added later. In its entirety, the optical bench on the IREA-CNR Potomac is a robust, highly stable system that allows for easy adjustment, alignment, user maintenance and future upgrades.

Figure 6. PMTs and the fluorescence arm of the IREA-CNR Potomac.

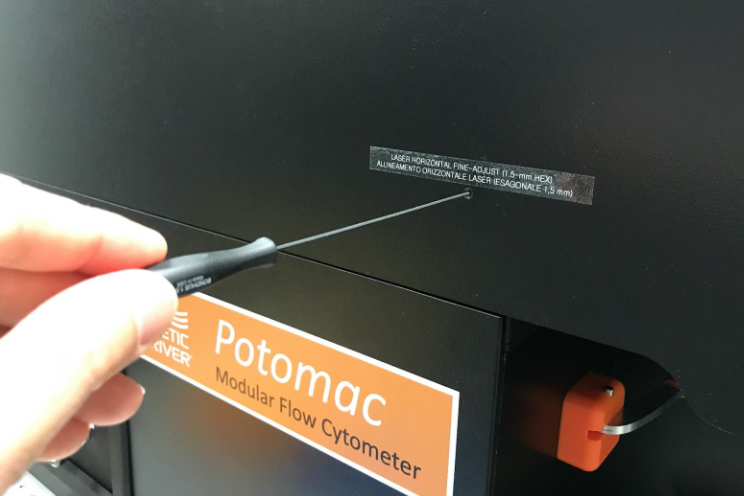

Figure 7. Laser fine-alignment port.

External Laser Adjustment System

Having an external light source can present an alignment challenge for the user, as laser beams from external sources naturally propagate over larger distances than beams from built-in lasers, and their pointing stability may not be sufficient to guarantee permanent signal optimization. To solve this problem, Kinetic River designed and installed a laser fine-adjustment system, shown in Figure 7, to allow the user to fine-tune the alignment of the external laser without taking the top off the Potomac. To use the laser adjustment system, the user inserts a provided tool into a dedicated port on the front panel of the instrument. The tool controls a stage that provides fine horizontal translation of the laser beam. This allows the user to optimize alignment of the external light source with the instrument under full operating conditions—avoiding burdensome iterations requiring lifting the cover, adjusting alignment, replacing the cover, and checking performance. As an added benefit, the fine-alignment tool also provides adjustability for the two built-in lasers, allowing the user to always have optimal beam-sample alignment.

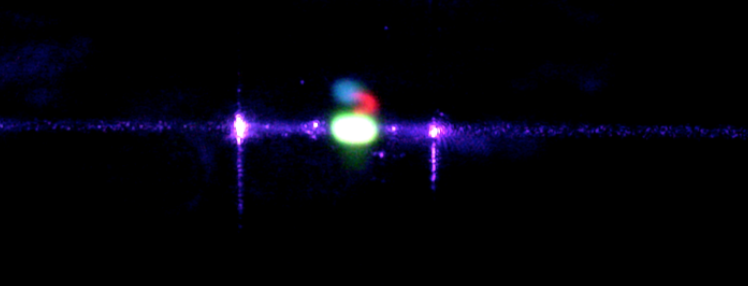

Microscope

A critical feature of the Potomac is the always- on flowcell-monitoring microscope. Kinetic River mounted a microscope to the flow cell; the microscope provides a continuous live video feed of the interrogation region, i.e., the region where the laser beam meets the sample stream (Figure 8). This innovation allows users to see in real time the sample core stream, and monitor any changes in core size as a result of pressure adjustments. The microscope comes equipped with a liquid lens, allowing remote adjustment of the focus through software. This microscope feature comes standard with all Kinetic River instruments, and provides a level of information to the flow cytometry user that is unparalleled across the industry.

Figure 8. Image of laser and sample core stream in the flowcell of the IREA-CNR Potomac.

Fluidic Control

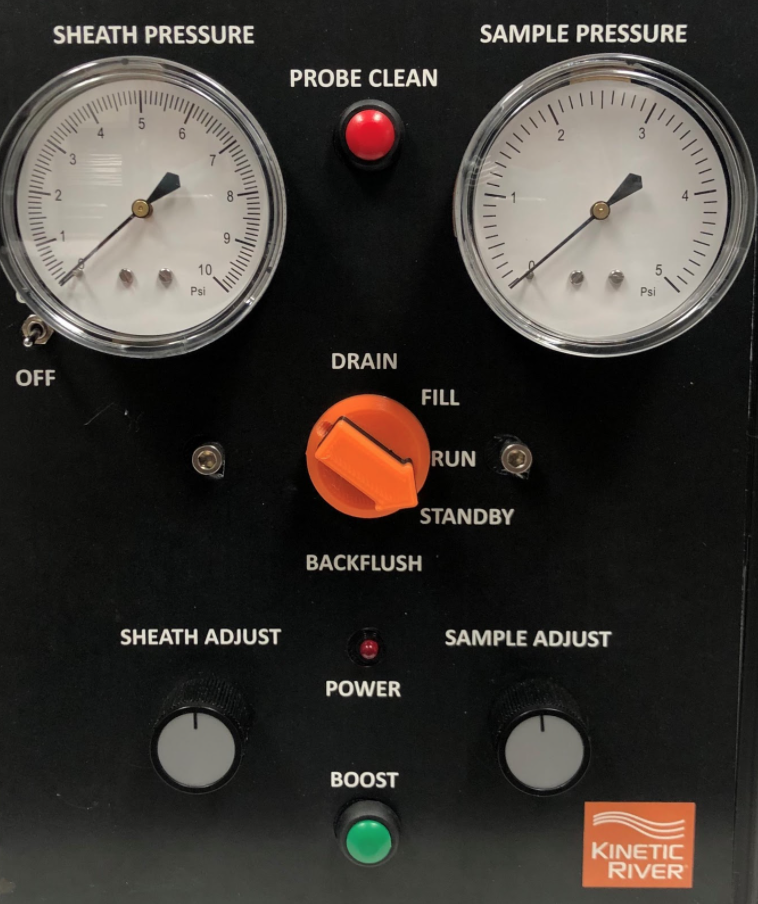

Kinetic River has designed and developed a flexible and customizable fluidic system to address the variety of needs of the diverse base of flow cytometry users. With a stable system architecture, the Shasta Fluidics Control Module (Figure 9) adapts to the requirements of the user while providing a stable core.

Pneumatic pumps provide constant pressure throughout the Shasta module, and dual-stage regulation on both the sheath and the sample lines provides stability and high-resolution adjustment capabilities for the user. Built-in features such as probe clean, sample boost, and automatic venting increase functionality of the module.

The Shasta is built into every flow cytometer manufactured at Kinetic River, and is also available as a standalone fluidic system for users with varied needs. Most imporantly, the Shasta can be customized for unique requirements, such as those at the National Research Council. The performance of the Shasta can be tailored to produce sample flow rates as low as 0.2 µL/min and as high as 200 µL/min.

Kinetic River also implemented user-friendly features such as the drip cup (for automatically catching probe-rinse fluid and routing it to waste; Figure 10), large sheath and waste tanks (to minimize the number of times they have to be refilled or emptied), an always-on scale (to notify the user when the sheath tank needs refilling), and a liquid level sensor (integrated with the user interface to alert the user when the waste tank is full).

Figure 9. Front panel of the Shasta Fluidics Control Module.

Figure 10. Drip cup.

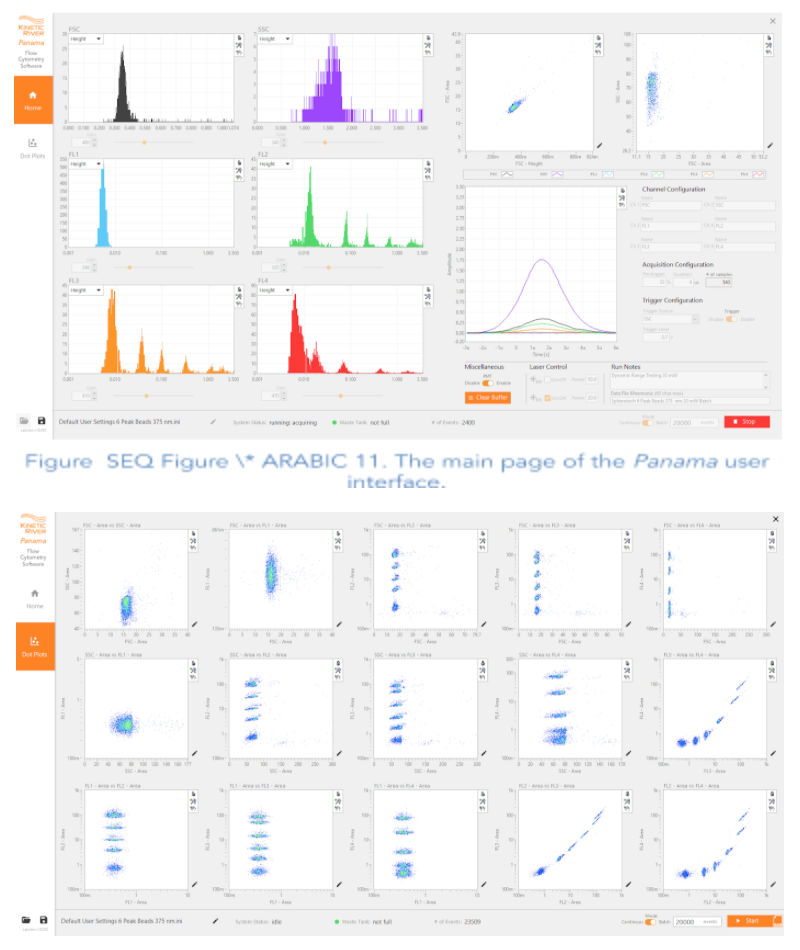

Figure 12. Cytograms on the Panama user interface.

Data Acquisition and User Interface

The data acquisition system that Kinetic River developed for the Potomac was driven by the processing power requirements needed to collect and digitize the large quantities of data that are acquired in a typical flow cytometery experiment. Once the proper hardware was sourced and installed, Kinetic River collaborated with software developer JKI to develop a brand-new user interface, the Panama, that provides seamless control over the instrument.

The Panama user interface features intuitive controls (Figure 11) that allow the user to turn on the lasers and adjust their power levels, enable PMTs and adjust their gains, and collect data on the Potomac, in both continuous and burst modes. It also includes a real-time display of all of the raw waveforms, as on an oscilloscope, for a deeper look at the behavior of each sample. It is an easy-to-understand, streamlined interface that provides flexible control of the instrument and displays complex information in intuitive ways. In developing this software, the engineers had to strike a balance between the sheer amount of data generated by the instrument and what actually needed to be displayed to the user. The end result is a functional user interface which displays important data to the user in a clear fashion (see, e.g., bivariate cytograms of all channel combinations in Figure 12), while storing the full data sets so they can be analyzed in more detail later.

Results

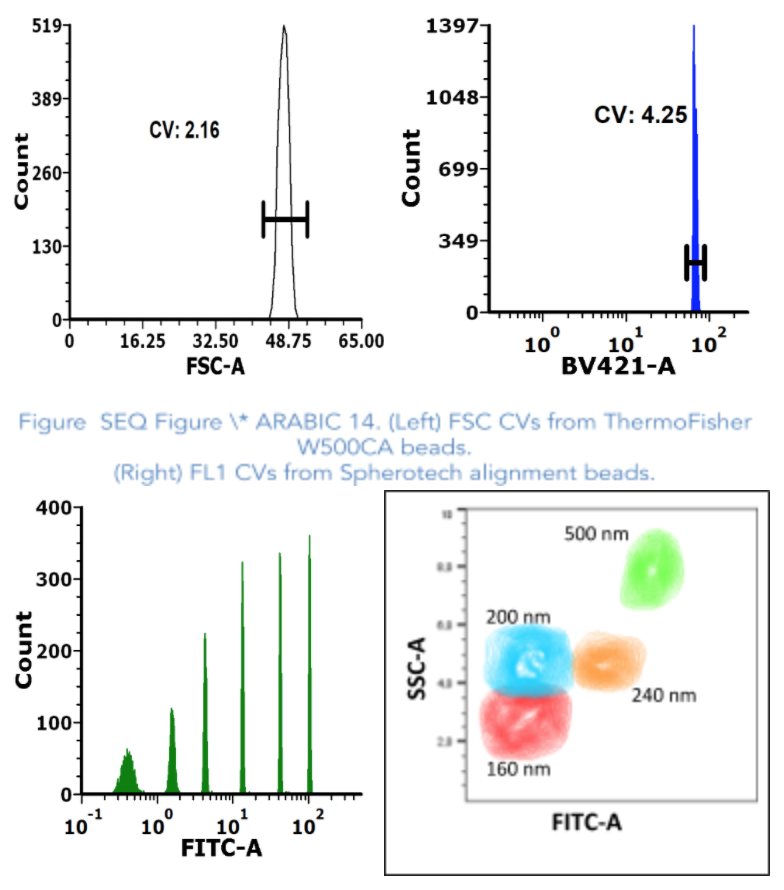

Kinetic River completed internal testing to characterize the Potomac performance. The simultaneous sampling rate on all channels is 10 MS/s to capture waveforms in rich detail, while event rates are over 5,000 event/s in Continuous Mode and over 10,000 event/s in Batch (or burst) mode. The sample core stream is stable and adjustable, with the ability to have sample flow rates as low as 18 µL/min and high as 133 µL/min. Transit times are adjustable between 2.0 µs and 7.0 µs. Instrument Coefficients of Variation (CVs) provide measures of stability, uniformity, and optical system quality: Figure 13 shows scattering CVs from polystyrene beads and fluorescence CVs from hard-dyed beads. Dynamic-range and linearity results from Spherotech 6-Peak Rainbow calibration beads (into the green FITC channel) are shown in Figure 14, together with measurements of a set of Megamix-Plus nanoparticle calibration beads, showing resolution down to at least 160 nm.

After completing internal testing, the instrument was shipped to our European sales and service partner, CytoFlowService. They performed post-shipping system testing and alignment verification, installed the system at the user site, and trained users on its operation.

Figure 13. (Left) Spherotech 6-peak Rainbow beads, excited at 405 nm, measured at 535±25 nm. (Right) Set of Megamix nanoparticles measured simultaneously with both 375-nm and 405-nm lasers.

Conclusion

Kinetic River designed, developed, built, and delivered a completely customized flow cytometer for the National Research Council in Naples, Italy. The Potomac is packed with state-of-the-art features, including unique all-violet/ultraviolet excitation, a stable and versatile fluidic system, nanoparticle sensitivity, and an intuitive user interface. This unique flow cytometer will allow scientists to conduct first-of-their-kind, label-free studies of samples for water-quality testing and cell biology applications.