UC Davis / NSF Project

Case Study:

Custom Fluidics Control Module

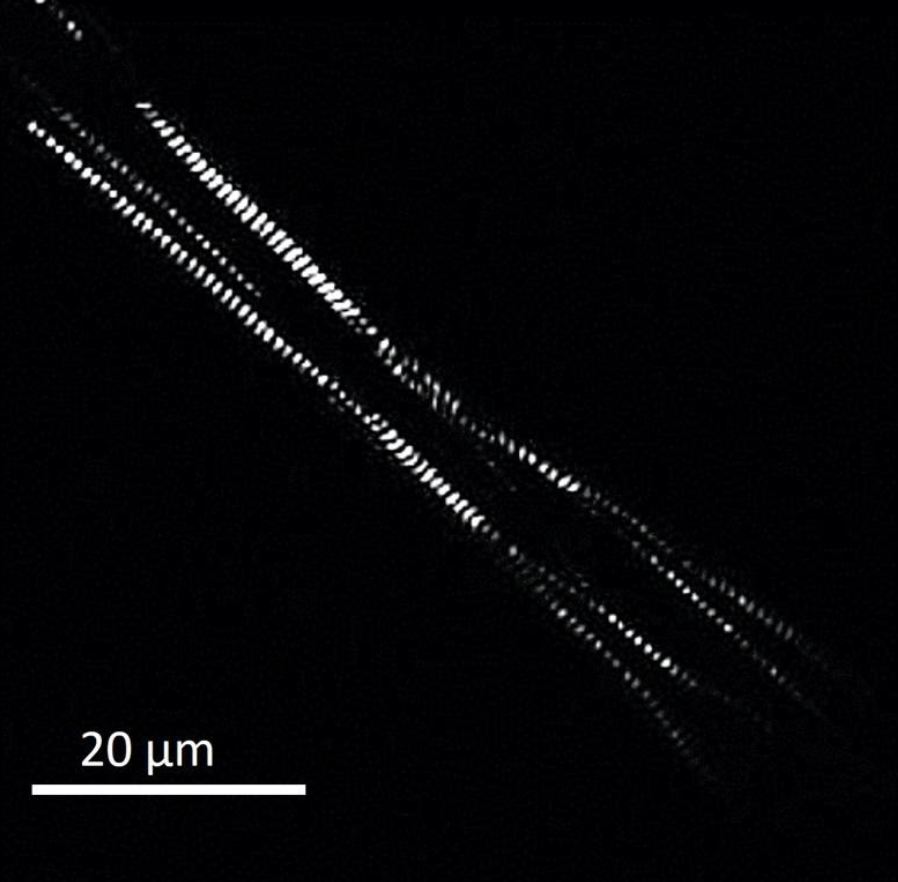

Stem cells are the focus of more and more research efforts because of their potential for live-saving treatments. Professor James Chan at the University of California, Davis, works with stem-cell-derived cardiomyocytes (SC-CMs; see Figure 1), a type of heart cell used, among other things, to screen drug candidates for toxicity. With the help of a research grant from the National Science Foundation, Prof. Chan is developing new label-free methods to identify and purify SC-CMs. His techniques require exquisitely controlled fluidics to drive the cells through the laser interrogation region on a microfluidic chip. Prof. Chan approached Kinetic River to design and develop a custom fluidics control module to be integrated into his optical analysis setup.

Thanks to the extensive experience gained in developing custom fluidics (like the Shasta control module used in our flow cytometers), we were able to design and build a custom module capable of meeting the strict requirements needed for Prof. Chan’s research. The main design challenge was achieving the ultralow flow rates that Prof. Chan’s studies require. This was achieved using a combination of design and component selection choices, resulting in sample flow rates as low as 0.25 µL/min—about 100 times lower than in typical flow cytometers. The custom module built for Prof. Chan’s setup also offers the ability to continuously adjust pressures for both sheath and sample flows.

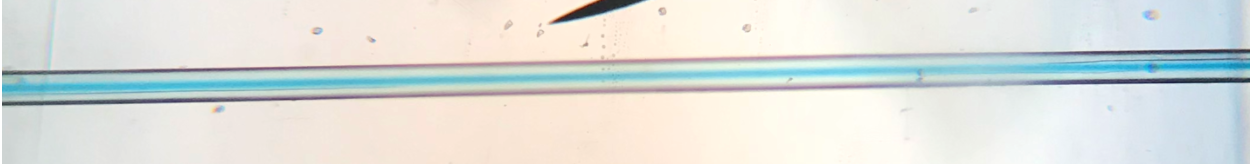

Manufacturing and testing of the custom module was done at KRC’s facilities in Mountain View, California. Internal testing was performed to ensure formation and stability of the sample core stream in the microfluidic chip (Figure 2), as well as to verify flow stability under the ultralow flow rate conditions required for Prof. Chan’s label-free cardiomyocyte studies.

Figure 1. Microscopy image of stem-cell-derived cardiomyocyte, with individual myosin bundles visible as elongated spots. Courtesy James Chan / UC Davis

Figure 2. Formation of core stream (blue) within the flow channel of a test microfluidic chip.

Transversal channel width is 300 µm.

The completed module (Figure 3) was then brought to Prof. Chan’s laboratory at UC Davis. The design engineer for this project performed the installation, delivered training for members of Prof. Chan’s group, and provided them with troubleshooting support as they familiarized themselves with operation of the module. This NSF-funded project produced a precise, highly stable microfluidic control module, which enables the researchers at UC Davis to conduct repeatable and innovative experiments.

Figure 3. Custom fluidics control module designed for Prof. Chan’s group at UC Davis. Visible are the sheath and waste tanks (left), the control panel and main module (center), and the sample probe assembly (right).